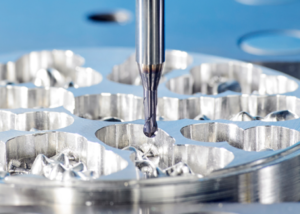

The need for dental implants has grown steadily in step with the increase in the aging global population. Accordingly, many companies are now actively developing dental CAD/CAM machines, and they compete by developing their own proprietary tool shapes. To meet the demand, KORLOY has released the T Endmill that helps customers stay ahead of the competition with a customized tool for each machine.

Dental CAD/CAM technology is continuously developing by taking advantage of X-ray and oral scanners, and many manufacturers have commercialized CNC machines to automate the previous manual process of manufacturing implants. As a result, machining time is significantly reduced, resulting in improved productivity and demands for tools with longer life.

The typical materials of dental prostheses, such as zirconia, titanium, Co-Cr, wax, and PMMA, have different physical and mechanical properties, and each requires an optimized tool solution.

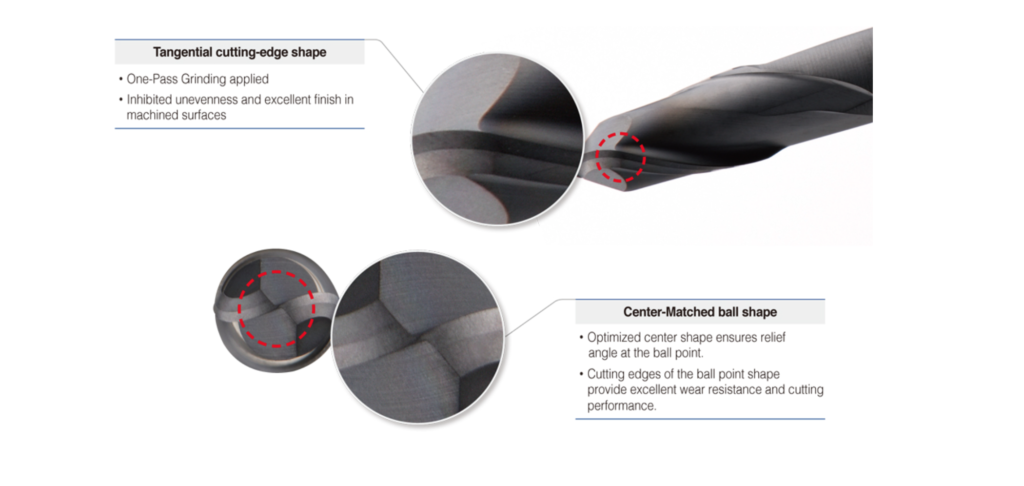

T Endmill uses a specialized grade for each workpiece: ND3000 for zirconia, and PC2510 for titanium and Co-Cr, and guarantees excellent machinability thanks to its optimized blade design.

580 Pradit Manutham Road, Phlapphla, Wangthonglang, Bangkok 10310

By clicking “Accept”, you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts. Privacy Policy