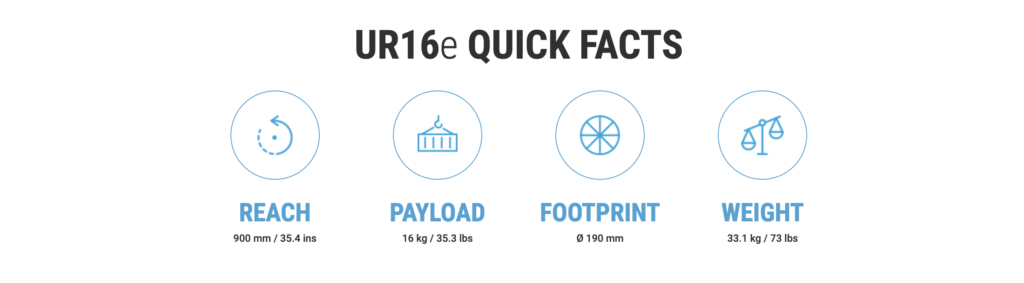

The utility of this collaborative industrial robot is unmatchable. The UR16e is built for heavy duty tasks like machine tending, material handling, packaging, material removal, and screw and nut driving applications. It handles an exceptional 16 kg of payload that is especially useful for carrying heavy end of arm tooling and can lift multiple parts in a single pick, making tasks much more efficient by achieving shorter cycle times. UR16e is also offered as an OEM robot system and with a 3-Position Teach pendant. Are you looking for the CB3 model you can find it here

Collaborative robots can work almost anywhere and automate almost anything. They free people up to do what they’re good at: creating, collaborating, and doing something amazing.

Collaborative robots, or cobots, expand capacity for businesses of all sizes. They can change the way employees work; integrate seamlessly with existing processes, layouts, and equipment; and improve quality across many applications. Collaborative automation makes the workplace safer and lets workers pursue more valuable tasks.

The e-Series family has four members – the UR3e, UR5e, UR10e, and UR16e. Each cobot offers a different reach and payload, and they share the same ease of use and dependability that makes them a valuable addition to any production facility.

Subject to risk assessment, e-Series cobots can typically work alongside skilled operators on the production line, thanks to built-in configurable safety functions. Our cobots are certified by TÜV NORD for ISO 10218-1 and safety functions are rated as Cat.3 PL d according to ISO 13849-1. Safety is one of the pioneering features of collaborative robotics, and our users can meet demanding safety standards while exploring the unlimited applications of our cobots. Greater productivity, improved product quality, and peace of mind are ways we’re making automation accessible to everyone.

Universal Robots is the market leader in collaborative robots. Since introducing the world’s first commercially viable cobot in 2008, UR has developed a product portfolio including the UR3e, UR5e, UR10e, and UR16e, reflecting a range of reaches and payloads. Each model is supported by a host of Plug & Produce end effectors, software, and accessories in the UR+ certification program, allow- ing for flexible redeployment of one robot into several diverse applications.

Universal Robots has installed over 50,000 cobots worldwide automating every manufacturing industry.

Headquartered in Odense, Denmark, UR operates out of 21 regional offices in the Americas, Europe, and Asia-Pacific.

580 ถนนประดิษฐ์มนูธรรม แขวงพลับพลา

เขตวังทองหลาง กรุงเทพ 10310

By clicking “Accept”, you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts. Privacy Policy

คุณสามารถเลือกการตั้งค่าคุกกี้โดยเปิด/ปิด คุกกี้ในแต่ละประเภทได้ตามความต้องการ ยกเว้น คุกกี้ที่จำเป็น

ยอมรับทั้งหมด