The Nakashimada BT series as simple bolt formers and BTX series as parts formers. They are evolved from the TH series roller feed type multi-station parts formers which gained high reputation from aircraft industry. In particular, its merits are high accuracy despite its simple structure, stable continuous operation and operability with great ease.

The Nakashimada BT series as simple bolt formers and BTX series as parts formers. They are evolved from the TH series roller feed type multi-station parts formers which gained high reputation from aircraft industry. In particular, its merits are high accuracy despite its simple structure, stable continuous operation and operability with great ease.

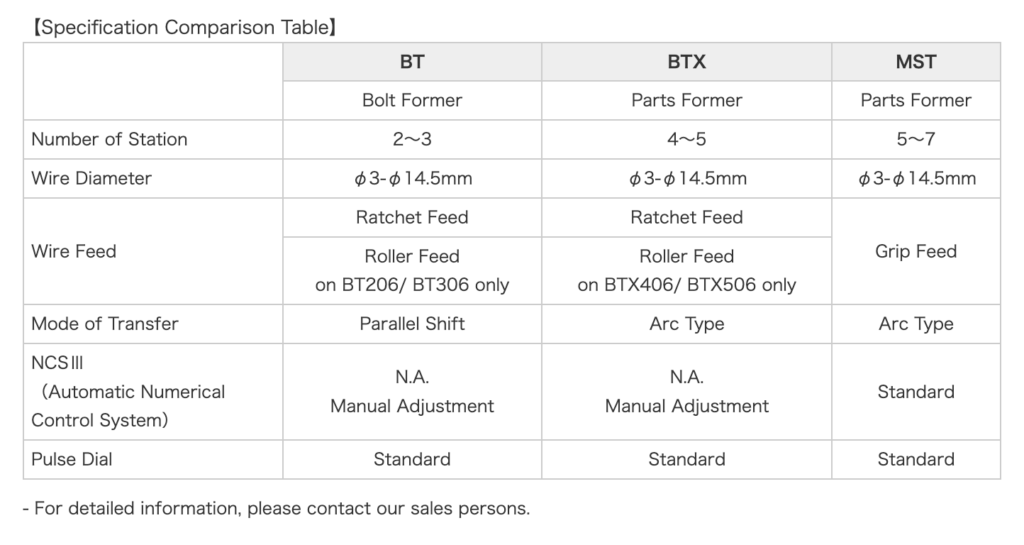

The MST series with Numerical Control System is still evolving responding to our customers’ requests. Our patented Pulse Dial is a standard feature on BT/BTX/MST series. It allows operator to move the ram forward and backward with small volume by turning a dial, so that job change over and subtle alignment can be performed easily and safely.

The BT/BTX series are designed as eco-friendly machines from its design stage with simplified equipment. While speeding up production speed, we manage to reduce overall electric and air consumption.

The Nakashimada MST series Multi-Die Finger Transfer Parts Formers are especially designed for high-value precision-formed products. While the production speed is an important issue, Nakashimada has put even more effort for its accuracy. As a result, the MST series have become the best selling parts former in the field of manufacturing quality aircraft parts and rivets.

As a successor to the TH series, MST series is now available from 3.0mm to 14.5mm in wire diameter and from 5 Die 5 Blow to 7 Die 7 Blow in configurations, feature fully computerized adjustments to minimize the changeover interval. This computer system, called NCS is standard on all MST machines and can memorize more than 3,000 different shapes of complex components. The die block, cutter and finger devices are integrated into the unit in the major models of the MST series and the unit can be lifted and turned towards operator side for easy adjustment. For transfer, fast arc movement is adapted and various functions such as extra parts discharge finger, short blank support, etc for more application.

580 Pradit Manutham Road, Phlapphla, Wangthonglang, Bangkok 10310

By clicking “Accept”, you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts. Privacy Policy