Machining of bearing parts generally used in automobile and general machinery industries requires toughness of cutting edge due to interrupted cutting condition and their high hardness. In addition, in deep grooving, tangled chips rolling up and scratching the workpieces causes the automatic machining inconsistent.

KORLOY’s newly launched CP chip breaker enhanced chip evacuation, chip breaking and strength of cutting edge in interrupted turning.

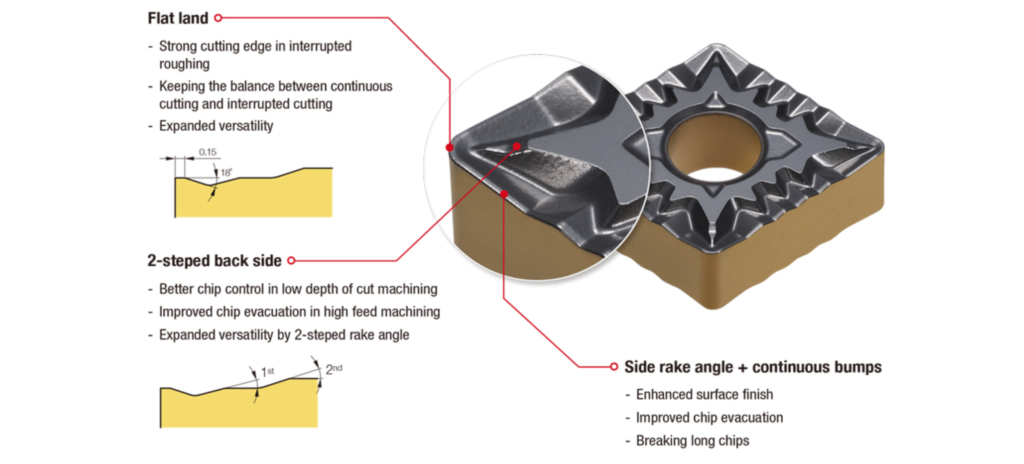

The CP chip breaker applied the strengthened land to protect cutting edge and adopted 2-stepped back chip breaker with side rake angle and continuous bumps ensuring longer tool life by preventing chattering in high feed cutting. With its excellent chip evacuaction and chip breaking performances, it realizes convenience in the automatic machining.

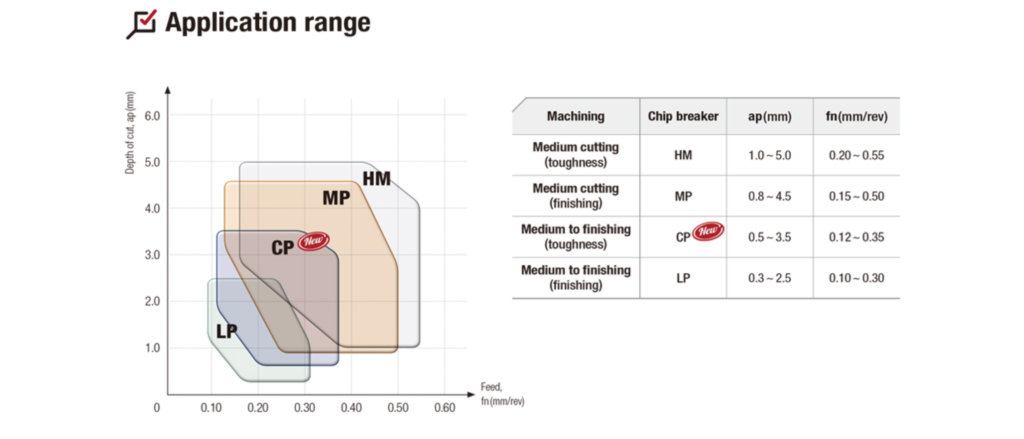

The combination of CP chip breaker realizing high feed machining with high toughness and chip evacuation and NC3215P/NC3225P enhancing wear resistance and chipping resistance provides the best solution realizing efficiency and high productivity in automobile parts machining.

580 Pradit Manutham Road, Phlapphla, Wangthonglang, Bangkok 10310

By clicking “Accept”, you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts. Privacy Policy