Workpieces made of casting used for automobile components and large metal molds machining have uneven surface which causes chattering.

Also in casting machining, tools for high depth of cut machining is needed due to its irregular depth of machining. However, it is hard to use the existing tool in high depth of cut machining because of high cutting load. In this cutting condition with interruption, impact and chattering actualize worse surface finish and fracture of tool due to lower machinability rigidity of tool.

KORLOY’s newly launched Triple Mill creates the solutions for those troubles and realizing high depth of cut machining.

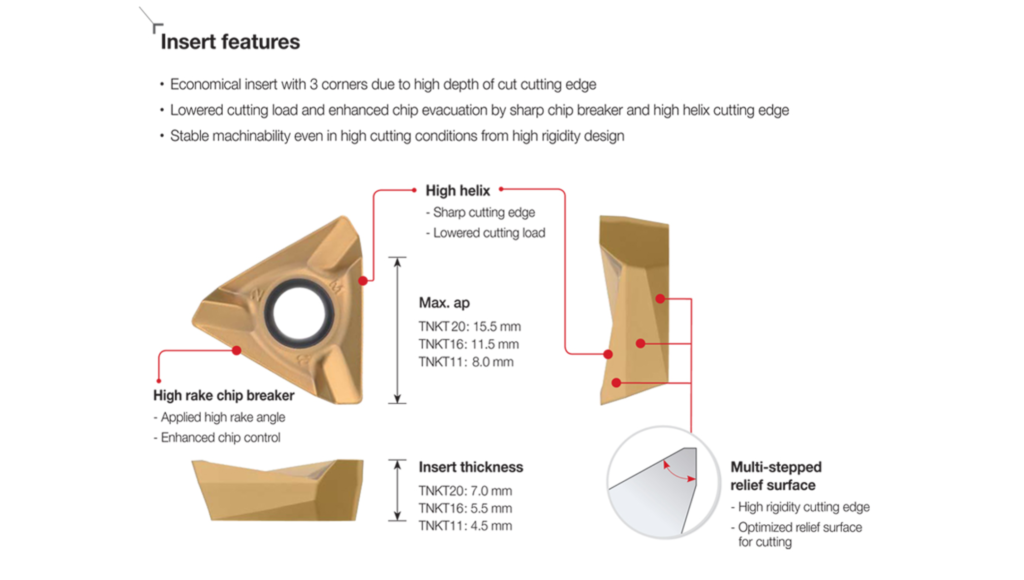

Triple Mill has applied a cutting edge with high depth of cut (Max. 15.5 mm) in single cutting with 3 corners allowing it to meet the most competitive price. In addition, the independent high rake chip breaker and high helix cutting edge reduces the cutting resistance and controls chattering in high depth of cut machining effectively. Its precise cutting edge with right angle ensures milling with high quality.

Specialized Triple Mill in high depth of cut machining and its optimized grade applied with each different cutting condition actualize excellent performance and increase customer’s productivity.

580 Pradit Manutham Road, Phlapphla, Wangthonglang, Bangkok 10310

By clicking “Accept”, you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts. Privacy Policy